About Woulf Group

Built by Operators. Designed for Owners.

Woulf Group is a warehouse and distribution center systems company founded on one simple belief:

operations should scale profitably, not break under growth.

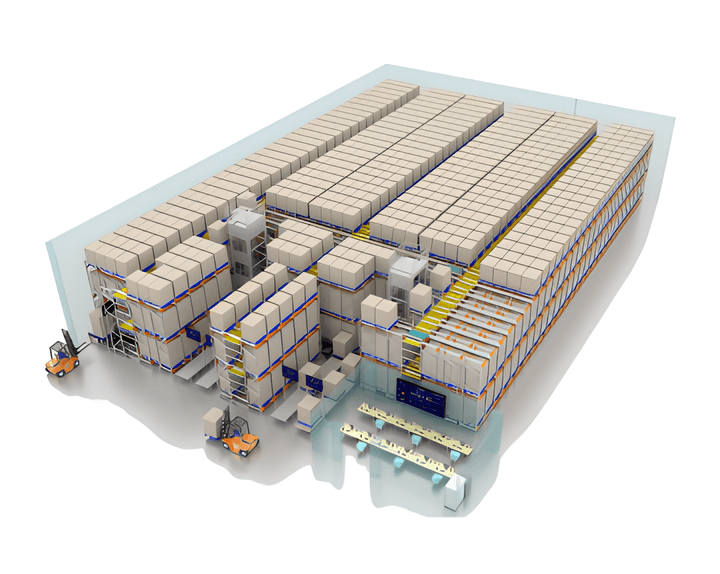

We design, engineer, and integrate complete warehouse and distribution center systems — from pallet racking and conveyor infrastructure to hybrid and fully automated pick, pack, and ship solutions — combining engineering discipline, automation, AI-powered software, robotics, and operational intelligence to increase throughput, reduce labor dependency, and drive long-term shareholder value.

We Think in Systems, Not Projects

Most firms sell components. Others sell labor.

Woulf Group designs systems.

Every warehouse and distribution center operates under real constraints — labor availability, capital, space, temperature, throughput, and cash flow. Our systems-level approach ensures every component works together:

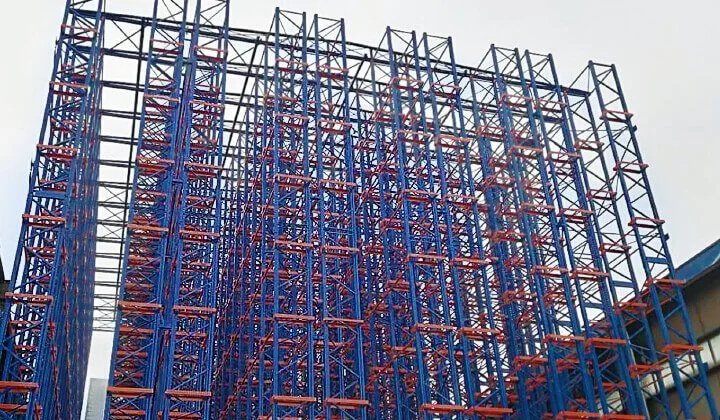

Pallet racking systems, including high-density and FIFO configurations

Conveyor systems and material flow automation

Hybrid manual-to-automation pick, pack, and ship operations

Fully automated fulfillment and AS/RS solutions

Cold and freezer storage, including temperature-controlled automation

Custom fabrication and engineered solutions

AI-powered software, robotics, and full system integration

The result is an operation that performs reliably under real-world volume and labor conditions.

Automation That Pays for Itself

Automation should not be implemented for novelty — it should produce measurable returns.

Woulf Group designs hybrid and fully automated systems that are justified by:

Labor savings and reduced dependency on scarce labor

Increased throughput and order velocity

Improved accuracy, uptime, and service levels

Predictable payback periods tied to operational performance

Our focus is building automation that earns its place on the balance sheet.

Owner-Level Consulting Meets Engineering Discipline

We work directly with owners, executives, and operators — not just project managers.

Warehouse and distribution center systems decisions directly impact:

Cash flow and working capital

Labor efficiency and scalability

Throughput, order accuracy, and customer experience

Long-term asset value and operational resilience

Our role is to align engineering and automation decisions with financial outcomes.

Built for Complexity and Scale

Our team brings decades of hands-on experience designing, building, and operating systems across:

Warehouses and distribution centers

E-commerce, DTC, and omnichannel fulfillment

Third-party logistics (3PL)

Manufacturing and industrial distribution

Cold storage and temperature-controlled environments

From pallet racking and conveyor systems to fully automated pick-pack-ship operations, Woulf Group specializes in complex facilities where standard solutions fall short.

The Woulf Group Advantage

Operator-first mindset — real warehouse and DC experience

Custom-engineered solutions — no templates, no one-size-fits-all

Integrated systems approach — racking, conveyors, automation, and software

ROI-driven automation — systems designed to pay for themselves

Future-ready architecture — AI and robotics built in, not bolted on

We don’t chase trends. We engineer performance.

Our Mission

To help owners and operators build warehouse and distribution center systems that scale intelligently, perform reliably, and generate lasting value.

If your warehouse or distribution center is becoming the bottleneck to your growth, Woulf Group exists to fix that.

Contact us

Interested in working together? Fill out some info and we will be in touch shortly. We can’t wait to hear from you!